Power That Can’t Pause, Air That Must Improve

Across rapidly expanding industrial and urban ecosystems, diesel generator (DG) sets remain the backbone of uninterrupted power. When the grid fails, DG sets step in instantly—keeping hospitals operational, data centers online, factories productive, and construction sites running without delay.

There’s no denying their importance. But there’s also no ignoring the downside: diesel exhaust emissions.

These emissions don’t just disappear. They linger in the air, affect surrounding communities, degrade air quality, and expose organizations to regulatory risk. Today, managing DG emissions is no longer optional—it’s a responsibility.

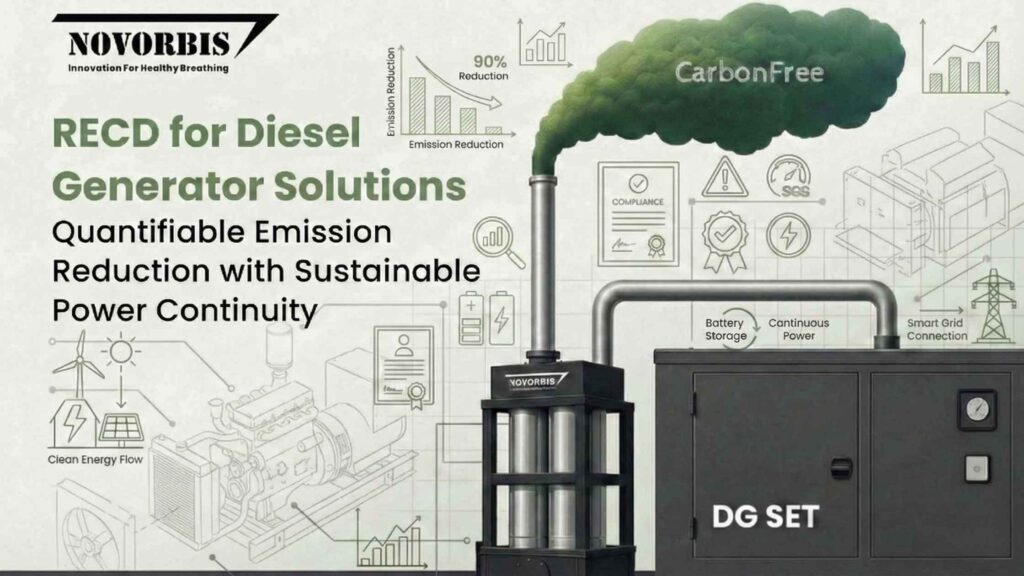

That’s where RECD for Diesel Generators: Measurable Impact on Air Pollution Control and Sustainable Power Continuity comes into focus.

Retrofit Emission Control Devices (RECDs) offer a practical way to reduce emissions without sacrificing power reliability. They integrate with existing DG sets, work in real operating conditions, and align with evolving environmental regulations. This blog explores how RECD technology delivers cleaner air while ensuring power never skips a beat.

Understanding RECD in Today’s Emission-Control Landscape

A Retrofit Emission Control Device (RECD) is an advanced exhaust after-treatment system designed to work alongside diesel generator sets—whether newly installed or already in operation.

In simple terms, RECD sits at the exhaust outlet and treats emissions before they enter the atmosphere. Harmful pollutants are filtered, oxidized, or neutralized, significantly reducing their environmental and health impact.

What makes RECD solutions effective is their balanced design:

- Efficient control of particulate and gaseous pollutants

- Stable operation across variable load conditions

- Minimal effect on fuel efficiency and engine performance

The DG set continues delivering reliable power, while RECD quietly takes care of the environmental side of the equation.

Pollutants Controlled by RECD Systems

Diesel exhaust contains multiple harmful pollutants. RECD systems are designed to address them comprehensively.

Particulate Matter (PM): The Invisible Hazard

Fine and ultrafine particulate matter is among the most dangerous pollutants produced by diesel engines. These microscopic particles can enter deep into the lungs and bloodstream, increasing long-term health risks.

Modern RECD systems reduce particulate emissions by up to 99.9%, resulting in noticeably cleaner air around DG installations—especially important in dense industrial zones and urban environments.

Nitrogen Oxides (NOx): Smog and Ozone Contributors

NOx gases contribute to smog, acid rain, and ground-level ozone. In cities and industrial clusters, they play a major role in deteriorating air quality.

Catalytic components within RECD systems help reduce NOx formation, improving local air quality and minimizing secondary pollution effects.

Carbon Monoxide (CO) and Hydrocarbons (HC)

Incomplete diesel combustion releases carbon monoxide and unburnt hydrocarbons—both toxic and potentially lethal in enclosed or populated areas.

Oxidation catalysts inside RECD systems convert these gases into less harmful compounds before they exit the exhaust.

Regulatory Compliance: From CPCB Norms to ARAI Type Approval

Emission norms for diesel generators are becoming increasingly strict, particularly for DG sets above 125 kVA. While CPCB compliance remains mandatory, higher-capacity generators are now expected to meet more advanced technical benchmarks.

This is where ARAI Type Approval plays a critical role.

ARAI approval validates:

- Emission performance under real operating loads

- Thermal safety at high exhaust temperatures

- Engine compatibility for medium and large DG sets

In this evolving compliance environment, Novorbis has achieved a significant milestone by securing ARAI Type Approval for its complete RECD range from 100 kW up to 771 kW, including approval for the 771 kW category on 19th December.

This confirms that RECD systems can now perform reliably at higher power ratings—where traditional solutions often struggle.

CarbonFree™: A Filterless RECD Designed for Large DG Sets

A major breakthrough in RECD technology is CarbonFree™, a compact, filterless emission control solution designed specifically for large diesel generators in the 750 kVA and 910 kVA range.

Traditional RECD systems rely on filtration, which can lead to soot buildup, clogging, increased backpressure, and frequent maintenance—especially under continuous high-load operation.

CarbonFree™ eliminates these limitations.

Key Advantages of CarbonFree™ Technology

- ARAI-certified coverage from 100 kW to 771 kW

- Filterless design with no clogging issues

- Ultra-compact footprint for space-constrained installations

- Near-zero exhaust backpressure, preserving engine performance

- Class 1 RECD classification with no secondary pollutants

- No silencer removal or additional structural support required

- Durable stainless-steel construction for long service life

This reflects a broader industry shift: emission control systems must now deliver compliance without compromise.

Intelligent Monitoring with AI-Based Diagnostics

Modern RECD systems go beyond passive emission control. AI-enabled onboard diagnostics continuously monitor key parameters such as:

- Exhaust temperature

- Differential pressure

- System health trends

This allows for predictive maintenance, early fault detection, and optimized performance—reducing downtime and maintenance costs while improving reliability.

Measurable Benefits of RECD Installation

Organizations that adopt RECD solutions experience tangible improvements.

Environmental Benefits

- Significant reduction in PM, NOx, CO, and HC emissions

- Improved ambient air quality

Operational Benefits

- Stable DG performance across all load conditions

- Reduced engine wear due to cleaner combustio

Strategic Benefits

- Strong regulatory compliance

- Improved ESG and sustainability credentials

- Enhanced trust with regulators and stakeholders

Industries Where RECD Is Essential

RECD adoption is especially critical in sectors that rely heavily on high-capacity DG sets:

- Manufacturing and industrial clusters

- IT parks and data centers

- Hospitals and healthcare campuses

- Educational institutions

- Construction and real estate projects

Retrofitting Existing DG Sets Without Disruption

One of the strongest advantages of RECD systems is their retrofit-friendly design. Installation typically involves:

- Minimal structural modification

- Short downtime

- No major changes to DG layout

This allows legacy generators to meet current and future emission norms without replacement.

Maintenance, Noise Reduction, and Long-Term Value

RECD maintenance is predictable and manageable, supported by intelligent diagnostics. Some configurations also reduce exhaust noise—an added benefit in urban and mixed-use areas.

Over time, RECD systems prove to be a long-term investment, not just a compliance tool.

FAQs: Clearing the Air Around RECDs

Do RECD systems affect generator performance?

Not significantly. Modern designs maintain near-zero backpressure, so power output stays consistent.

Are RECDs suitable for older DG sets?

Absolutely. That’s the beauty of retrofit solutions—they’re built for both new and existing installations.

Is ARAI approval really necessary?

For higher-capacity DG sets, yes. It provides verified assurance of safety and performance under real operating conditions.

Can RECDs help with ESG goals?

Without a doubt. Reduced emissions directly support environmental and social responsibility metrics.

Conclusion: Reliable Power with Cleaner Air

Diesel generators are here to stay. What must change is how their emissions are managed.

With RECD for Diesel Generators: Measurable Impact on Air Pollution Control and Sustainable Power Continuity, organizations no longer have to choose between reliable power and environmental responsibility.

By combining advanced emission control, ARAI-approved validation, and innovations like CarbonFree™, RECD transforms diesel power into a cleaner, compliant, and future-ready solution—supporting sustainable growth across industrial and urban ecosystems.

That’s a win for business, communities, and the environment.